H&M Oil and Gas Consulting

We strive for social responsibility, environmental stewardship, and economical profitability.

H&M Oil and Gas

At H&M Oil and Gas, we provide engineering consultancy services for upstream, midstream, downstream, LNG, and unconventional sectors of the oil and gas market. Asset owners need effective methods to assess and select the right initiatives for production gains or operating cost reduction. Our work is an essential step to support decision-taking in the concept, design and operational phases of an asset, meeting the production availability challenge by enhancing operational performance. Our core business circles around reliability studies and risk quantification. Quality of work and customer satisfaction ranks top in our priority list. Our team is based in Houston, Texas.

Area We Service

Upstream

Offshore Platform, Onshore Upstream, FPSO, FSO, FSRU, Subsea

Midstream

Gas Processing, Pipeline, Compressor Stations, Pumping Stations, Shipping, Trucking, Rail, Loading/Unloading Terminals.

Downstream

Refining, Chemical plants, Petrochemical Plants.

Other Service Areas

LNG, FLNG, Power Plants, Oil Sands, Geothermal…etc.

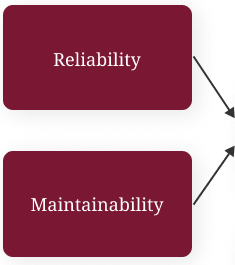

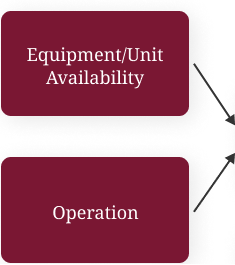

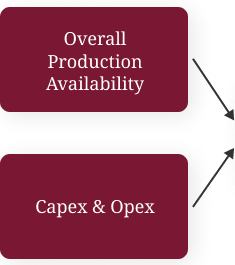

Why RAM?

RAM Stands for Reliability, Availability, and Maintainability study. RAM methodology provides a decision support to oil and gas companies across all sectors by using quantitative tools and a methodological approach to evaluate the production performance of new or existing development. Specifically, RAM analysis supports key decision makers across all phases of the project through:

Design optimization and integration

Design optimization and integration Operational strategy recommendations

Operational strategy recommendations Performance forecasting

Performance forecasting Process debottlenecking

Process debottlenecking Identification of key equipment/unit contributors to production losses

Identification of key equipment/unit contributors to production losses Reduction of asset risk

Reduction of asset risk Benchmarking of performance

Benchmarking of performance Mitigation of unforeseen risks

Mitigation of unforeseen risks Reduction of operating cost

Reduction of operating cost

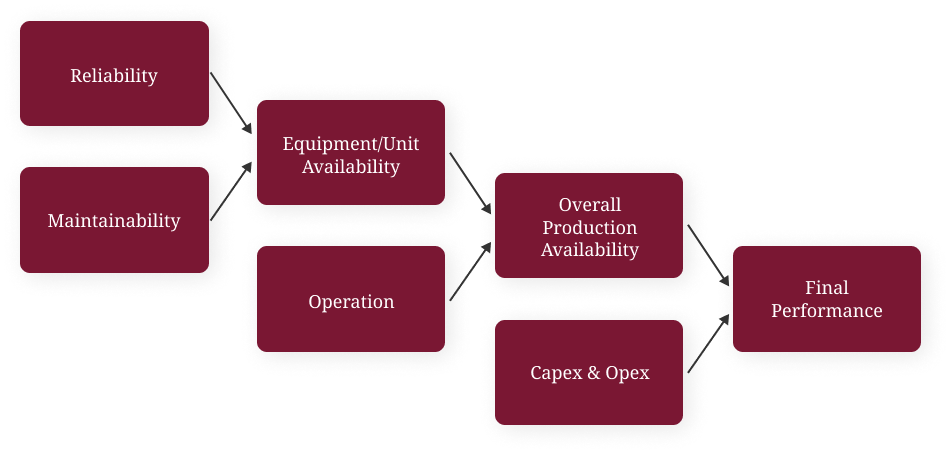

Reliability

Maintainability

Equipment/Unit Availability

Operation

Overall Production Availability

Capex & Opex

Final Performance

How RAM?

Following kick-off of the project, our team will gather all the information required to conduct the study. The information will be consolidated in a reference report that documents all the assumption and input data including equipment reliability data and configuration that will be used in the simulation model development. Using the agreed reference report, the base case RAM simulation model will be developed. The results generated will be presented to the project team. Using the outcome of the model, several sensitivity cases may be selected in order to evaluate different design and operational philosophies to maximize production and quantify risk. Finally, a RAM study report will be delivered at the end of the study.

Kick-off & Data

Collection

Reference

Report

RAM

Model

Sensitivity

Analysis

Study

Report